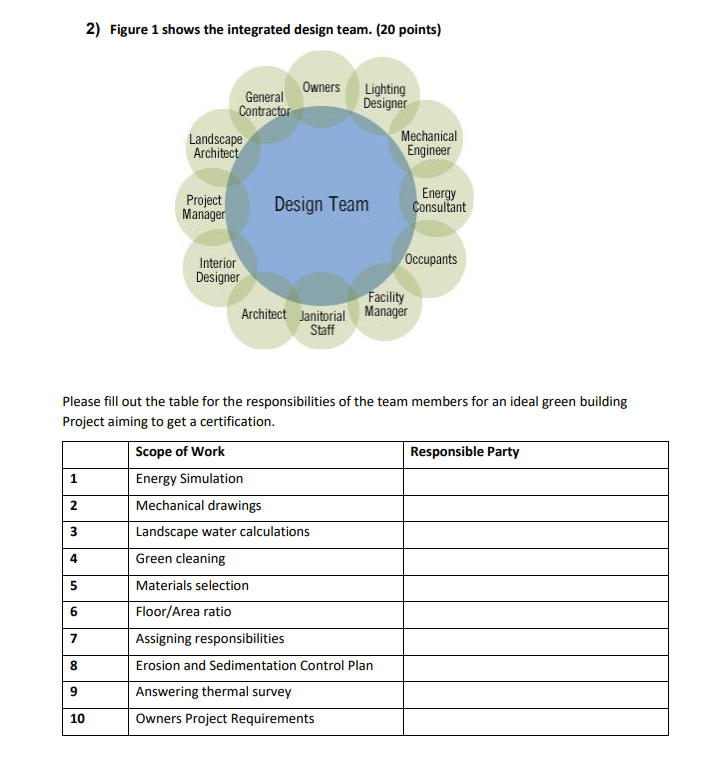

Patterns of Use

GIS-based Hydraulic Modeling of Rahimatpur Municipal Council Water Supply System. Maharashtra Jeevan Pradhikaran used Bentley software as its interoperable GIS-based solution to collaboratively design a sustainable water supply network for the population of Rahimatpur, India, optimizing energy consumption to reduce operating costs. Chapter 9 Water supply THE IMPORTANCE OF HYGIENE PROMOTION IN WATER SUPPLY AND SANITATION Introduction The principal purpose of programmes to improve water supply and sanitation is to improve health. On the other hand, the mere provision of water and sanitation infrastructure will not, in itself, improve health. To get the maximum benefit out of an. 2.1 water demand 8 2.2 water distribution systems 10 2.3 water distribution modeling 11 2.4 pumps 13 2.5 valves 17 2.6 tanks and reservoirs 18 2.7 controls devices 19 2.8 epa 20 3.0 laying out a project 21 3.1 existing data 22 3.2 schematic generally 22 3.3 pressure zones 23. Types of Water Distribution System. If topographic conditions are ideal, gravity distribution is used. This requires a reservoir at a sufficient elevation above the city so that water can reach to any part of the distribution system with adequate pressure without pumping. Water resource planners require hy.drologic data for the efficient, sound design and siting of water resource facilities. Since 1957 the U. Geological Survey has maintained an island-wide network of surface water stations and observation wells in Puerto Rico through the Federal-Common wealth cooperative program.

All life on Earth depends on water. Human uses include drinking, bathing, crop irrigation, electricity generation, and industrial activity. For some of these uses, the available water requires treatment prior to use. Over the last century, the primary goals of water treatment have remained the same—to produce water that is biologically and chemically safe, appealing to consumers, and non-corrosive and non-scaling. If water systems are mismanaged, public health emergencies can occur, such as in Flint, MI in 2014.

Water Uses

- In 2015, total U.S. water use was approximately 322 billion gallons per day (Bgal/d), 87% of which was freshwater. Thermoelectric power (133 Bgal/d) and irrigation (118 Bgal/d) accounted for the largest withdrawals.1 Thermoelectric power plants use water for cooling. Though 41% of daily water use is for power generation, only 3% of these withdrawals are consumptive.1 Irrigation includes water applied to agricultural crops along with the water used for landscaping, golf courses, parks, etc.1

- In 2015, California and Texas accounted for 16% of U.S. water withdrawals.1 These states along with Idaho, Florida, Arkansas, New York, Illinois, Colorado, North Carolina, Michigan, Montana, and Nebraska account for more than 50% of U.S. withdrawals.1 Florida, New York, and Maryland accounted for 50% of saline water withdrawals.1

Estimated Uses of Water, 20151

Sources of Water

- Approximately 87% of the U.S. population relied on public water supply in 2015; the remainder relies on water from domestic wells.1

- Surface sources account for 74% of all water withdrawals.1

- About 148,000 publicly owned water systems provide piped water for human consumption in 2020, of which roughly 50,000 (34%) are community water systems (CWSs). 9% of all CWSs provide water to 78% of the population.2

- In 2006, CWSs delivered an average of 96,000 gallons per year to each residential connection and 797,000 gallons per year to non-residential connections.3

Sources of Water Withdrawals, 20151

Energy Consumption

- 2% of total U.S. electricity use goes towards pumping and treating water and wastewater, a 52% increase in electricity use since 1996.4 Cities, on average, use 3,300-3,600 kWh/million gallons of water delivered and treated. Electricity use accounts for around 80% of municipal water processing and distribution costs.5

- Groundwater supply from public sources requires 2,100 kWh/million gallons—about 31% more electricity than surface water supply, mainly due to higher water pumping requirements for groundwater systems.4

- The California State Water Project is the largest single user of energy in California, consuming between 6-9.5 billion kWh per year, partially offset by its own hydroelectric generation. In the process of delivering water from the San Francisco Bay-Delta to Southern California, the project uses 3%-4% of all electricity consumed in the state.6,7

Water Treatment

- The Safe Drinking Water Act (SDWA), enacted in 1974 and amended in 1986 and 1996, regulates contaminants in public water supplies, provides funding for infrastructure projects, protects sources of drinking water, and promotes the capacity of water systems to comply with SDWA regulations.8

- Typical parameters that the U.S.EPA uses to monitor the quality of drinking water include: microorganisms, disinfectants, radionuclides, organic and inorganic compounds.9

- 91% of CWSs are designed to disinfect water, 23% are designed to remove or sequester iron, 13% are designed to remove or sequester manganese, and 21% are designed for corrosion control.3

Size Categories of Community Water Systems2

Life Cycle Impacts

Infrastructure Requirements

- The 2015 Drinking Water Infrastructure Needs Survey and Assessment found that U.S. water systems need $472.6 billion of investment by 2035 to continue providing clean safe drinking water.10

- $312.6 billion of the total national investment need is for transmission and distribution. The needs are for treatment ($83.0 billion), storage ($47.6 billion), source development ($21.8 billion), and other systems ($7.5 billion).10

- Water systems maintain more than 2.2 million miles of transmission and distribution mains.10 In 2020, the average age of water pipes in the U.S. is 45 years old -- an increase in average age from 25 years old in 1970.11 240,000 main breaks occur each year in the U.S., disrupting supply and risking contamination of drinking water.12

need by 2035, by Project Type10

Electricity Requirements

- Supplying fresh water to public agencies required about 39 billion kWh of electricity in 2011. This energy intensity increased by 39% beyond the 1996 values, mostly due to population growth and expansion of treatment facilities. This trend will likely continue in the coming years.4

- Household appliances contribute greatly to the energy burden. Dishwashers, showers, and faucets require 0.312 kWh/gallon, 0.143 kWh/gallon, and 0.139 kWh/gallon, respectively.13

Life cycle energy use for ann arbor water treatment plant13

Consumptive Use

- Consumptive use is an activity that draws water from a source within a basin and returns only a portion or none of the withdrawn water to the basin. The water might have been lost to evaporation, incorporated into a product such as a beverage and shipped out of the basin, or transpired into the atmosphere through the natural action of plants and leaves.1

- Agriculture accounts for the largest loss of water (80-90% of total U.S. consumptive water use).15 Of the 118 Bgal/d freshwater withdrawn for irrigation, over half is lost to consumptive use. Of the 133 Bgal/d of withdrawals for thermoelectric power in the U.S., 3% is consumed (4.31 Bgal/d).1

Solutions and Sustainable Alternatives

Supply Side

- Major components that offer significant energy efficiency improvement opportunities include pumping systems, pumps, and motors.16

- Periodic rehabilitation, repair, and replacement of water distribution infrastructure would help improve water quality and avoid leaks.10

- Right-sizing, upgrading to energy efficient equipment, and monitoring and control systems can optimize systems for the communities they serve, and save energy and water in the process.5

- Achieve on-site energy and chemical use efficiency to minimize the life cycle environmental impacts related to the production and distribution of energy and chemicals used in the treatment and distribution process.

- Reduce chemical use for treatment and sludge disposal by efficient process design, recycling of sludge, and recovery and reuse of chemicals.

- Generate energy on-site with renewable sources such as solar and wind.17

- Effective watershed management plans to protect source water are often more cost-effective and environmentally sound than treating contaminated water. For example, NYC chose to invest between $1-1.5 billion in a watershed protection project to improve the water quality in the Catskill/Delaware watershed rather than construct a new filtration plant at a capital cost of $6-8 billion.18

- Less than 4% of U.S. freshwater comes from brackish or saltwater, though this segment is growing. Desalination technology, such as reverse osmosis membrane filtering, unlocks large resources, but more research is needed to lower costs, energy use, and environmental impacts.4

Demand Side

- Better engineering practices:

- Plumbing fixtures to reduce water consumption, e.g., high-efficiency toilets, low-flow showerheads, and faucet aerators.19

- Water reuse and recycling, e.g., graywater systems and rain barrels.20

- Efficient landscape irrigation practices.20

- Better planning and management practices:

- Pricing and retrofit programs.19

- Proper leak detection and metering.20

- Residential water audit programs and public education programs.19

Center Pivot Irrigation System21

- Dieter, C., et al. (2018) Estimated use of water in the United States in 2015. U.S. Geological Survey Circular 1441.

- U.S. Environmental Protection Agency (EPA) (2020) Government Performance and Results Act (GPRA) Inventory Summary Report.

- U.S. EPA (2009) 2006 Community Water System Survey.

- Electric Power Research Institute (2013) Electricity Use and Management in the Municipal Water Supply and Wastewater Industries.

- Congressional Research Service (2017) “Energy-Water Nexus: The Water Sector’s Energy Use.”

- California Department of Water Resources (2020) Producing and Consuming Power.

- California Energy Commission (2020) Water-Energy Bank.

- Tiemann, M. (2017) Safe Drinking Water Act: A Summary of the Act and Its Major Requirements. Congressional Research Service.

- U.S. EPA (2017) “Table of Regulated Drinking Water Contaminants.”

- U.S. EPA (2018) Drinking Water Infrastructure Needs Survey and Assessment – Sixth Report.

- Water Finance and Management (2017) “Bluefield: CAPEX for Pipe Suppliers to Hit $300 Billion Over Next Decade.”

- American Society of Civil Engineers (2017) 2017 Infrastructure Report Card: Drinking Water.

- Tripathi, M. (2007) Life-Cycle Energy and Emissions for Municipal Water and Wastewater Services: Case-Studies of Treatment Plants in US.

- Abdallah, A. and D. Rosenberg (2014) Heterogeneous Residential Water and Energy Linkages and Implications for Conservation and Management. Journal of Water Resources Planning and Management, 140(3): 288-297.

- U.S. Department of Agriculture, Economic Research Service (2015) “Irrigation & Water Use Background.”

- Water Research Foundation (2011) Energy Efficiency Best Practices for North American Drinking Water Utilities.

- U.S. EPA (2017) “Energy Efficiency for Water Utilities.”

- Chichilnisky, G. and G. Heal (1998) Economic returns from the biosphere. Nature, 391: 629-630.

- U.S. EPA (2012) “How to conserve water and use it efficiently.”

- U.S. EPA (2020) “Water Management Plans and Best Practices at EPA.”

- Photo courtesy of U.S. Department of Agriculture, Natural Resources Conservation Service.

Water Network Systems Operations and Maintenance Training by TONEX

Water Network Systems Operations and Maintenance Training provides practical skills and knowledge and safe practices and procedures in operating and maintaining water distribution systems and networks.

Water Network Systems Operations and Maintenance Training course is designed to develop the knowledge and skills to effectively operate, maintain and control a water networking system and distribution system with topics such as water distribution system operators, procedures operations and maintenance for clear wells, storage tanks, functional elements, components and features of distribution system facilities, operating and maintaining distribution systems and networks, maintaining water quality in the network, disinfecting new and repaired facilities, and methods and techniques for hazard control and safe procedures and programs.

Learning Objectives:

After attending this course the participant will be able to:

- Understand the fundamentals of water network system

- List Characteristics of water network system and Distribution System Operation and Maintenance

- Operate water network system

- Maintain a water network system

- Test and control water a water network system

- Design and read a water network map

- List water Quality Considerations in Distribution Systems and water networks

- List Disinfection and Safety procedures and best practices

- Use applications and tools to analyze, operate and design a water network

- The Water Distribution System Operator

Prerequisites:

- Understanding of a basic water network

- Work experience in a primary water network

- Basic computer skills

Course Content

Introduction to Water Systems Networking

- Anatomy of a water system

- Water system classifications

- Water systems networks

- Classification of water systems

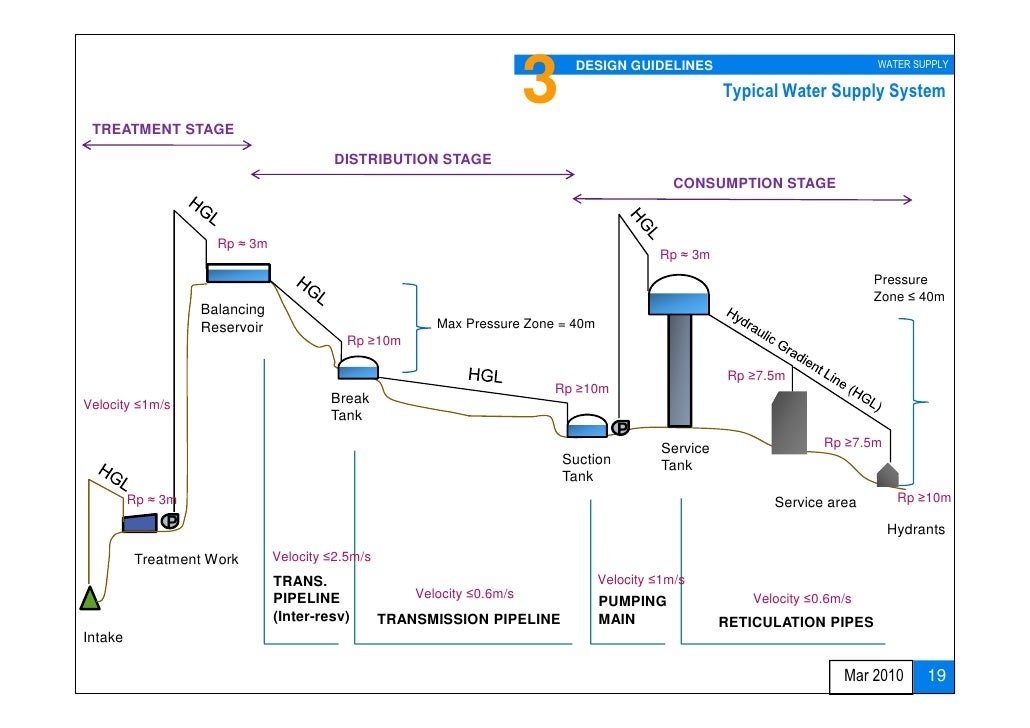

- Water supply system concepts

- Fundamental considerations

- Water distribution systems

- Continuous availability of water supply

- Water supply considerations

- Water treatment plants

- Water quality monitoring

- Water distribution system design concepts

- Water supply source classifications

- Water system components

- Calculate capacities and volumes, head and pressure and flow rates

- Water purification processes

- Calculate chemical dosage

- Describe the disinfection process and the chemicals used in water network system

- Type of water network system and modern water network system

- A brief history of water network

- Network hydraulics, fluid properties and theory

- Source and chemical characteristics of water

- Pre-treatment and water standards

- Potable water quality management

- Water sampling procedures and analysis

- Pressure drop calculations in different water networks and fittings

- List type and applications of typical water storage facilities

Importance of Operation and Maintenance

- What is Operation and Maintenance (O&M)?

- Cost-effective, efficient, and sustainable water systems

- O&M built into operational programs

- Constrains of Operation and Maintenance

- Scope of work off the O&M Network

- Available O&M Tools

- Case Study

- Promoting Operation and Maintenance

- Design of system management

- Training

- Spare parts

- Finance

- Examples of Inappropriate O&M

- Water Leakage Prevention Measure

- Corrective Measures

- Preventive Measures

- Technology Development

- Leakage Survey

- Leakage Repair

- Pipe Laying and Construction Supervision

- Piping Design Procedure/Process

- Supervision System

- O&M requirements

Protection for Water Network Systems

- Line protection function

- Valves, pumps, pipe protection

- Transformer protection function

- Compensator protection function

- Basbar protection function

- Circuit-breaker, back up protection function

- Monitoring and evaluation function

- Key Issues for Improvement of O&M

- Operation and maintenance requirements

- Monitoring for effectiveness

- Planning tools

Operation and Management (O&M) of a Water Network System

- The Supply and Operation

- Water network major components

- Mechanical and electrical system components

- Water-gate, valves, stop cocks, motors, and instruments

- Hydraulic of water system networking

- Water network system design

- Pipeline materials, Type and design

- Distribution and transmission system valves (operation, installation, check and control)

- Water pump type, selection, installation, operation and intakes.

- System design for water pumping

- Variable- speed pumping

- Operation and management of a water network (daily operation)

- Monitoring process information

- Operation records and reports

- Electrical control systems

Maintenance Water Network Systems

Network Survey Managerdesign Water Supply Systems

- Test water network system

- Failure mode for water network system

- Flow problem and control

- Pressure problem and control

- Test and control valves, pipes, pumps and switches

- Problem and reduce vibration and noise

- Investigation of system contamination

- Take off-line

- Shutting down system

- Power outages

- Power Consumption

- Water distribution system flushing

- Leakage prevention and control;

- Maintenance and adequate disinfectant residual

- Friction losses

- Maintenance information system

- Retrofitting existing water pumping system

- Daily operation problem and repairs

Network Survey Managerdesign Water Supply System

Security, Safety, and Administrative Procedures

- Water Network System Security

- Health and Safety Regulation

- Hazardous Materials and Safety

- Normal/abnormal conditions

- Normal characteristics of water Chemical

- Monitor, evaluate, adjust chlorine disinfection

- Ability to calculate dosage rates

- Inspect, maintain, repair flow measurements

- Inspect, maintain, repair well operation

- Diagnose/troubleshoot process units

- Leak detection

- Processes in normal operating condition

- Disinfectants concepts and properties

- Disinfectant processes and design parameters

- Disinfection calculations

- Proper handling and storage of disinfectants

- Lifting procedures

- Regulations

- Microbiological

- Safety plans and apply safety procedures

- Safety hazards verbally and in writing

- Safe work habits

- Chemical hazard communication

- Electrical grounding

- Potential impact of disasters on facility

- Slips, trips, and falls

Request More Information